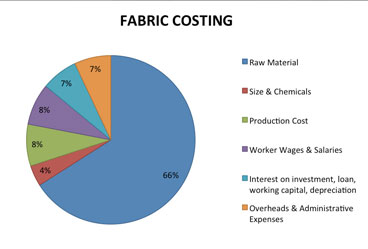

The textile industry is a global commodity chain with fabric being one of the most important pieces that determine how much the final product will cost. Textile manufacturing involves several steps, from cotton picking through spinning and weaving to finishing. The industry serves as a source of livelihood for over 45 million people in India. To fully understand the creation of fabric and its costs you may want to know that there are different parameters involved—these can be understood as direct and indirect costs. The direct costs would include:

1. The cost of the raw material(fiber or yarn), which makes up 66 percent of the total cost, the Raw material cost includes the cost of fiber or yarn

GSM:The amount of raw material used to make a fabric is reflected by the weight or the GSM (gram/sq meter) of the fabric. For the same variety of the fabric as the GSM increases, the cost increases. However, when the yarn becomes very fine, the cost of spinning and weaving supersedes the role of GSM. So even when the GSM is similar the cost of fabric with finer yarns is more.

COUNT OF YARN:The yarn cost will depend on the count of the yarn—the finer the yarn, the more expensive it can get. Combed yarns are more expensive than carded yarns because yarn realization is only about 70 percent due to the removal of short fibers, while it is almost 88 percent in the case of carded yarn. All finer counts above 40 are generally combed yarns. The sizing cost also depends upon the count of the yarns. As the count becomes finer, the size and chemical cost increases because better quality size and chemicals are required for better strength.

TYPE OF FIBER: The cost of the fiber will depend on the type and the quality of fiber. Various types of fiber would include cotton, linen, wool, silk, rayon, nylon, polyester, polyester cotton blend etc.

2. Cost of size and other chemicals,which make up 4 percent of the total cost. Dyeing costs depends on several variables.

WEIGHT: Dyeing lighter weight fabric reduces the cost of dyeing. This is because, capacity of the machine is expressed in weight of the material, so when dyeing lighter weight fabric, more length of the material can be processed at the same time, reducing the dyeing cost

SHADE:When considering the shade of the fabric, the lighter the shade the lower the cost. This is because the amount of dye and time required in the processing are less. For example, dyeing pastel shades takes one and a half times the time it will take to dye black and burgundy shades. The cost of dyeing also depends upon the class and quality of dyes used. Vat dyes are more expensive than reactive dyes, and better expertise is required for dyeing. So for the same shade, the cost of dyeing a fabric with Vat dyes is more than dyeing it with Reactive dyes. Also, within the same dye class, some colors are more expensive than the others. For example, turquoise and reds are more expensive. Some colors change their shades in different lights, this property is known as Metamerism. Therefore, if the shades need only be matched in two or three different lights then the cost is less, however, if the matching is required in all the six lights, better quality dyes are required and the cost is more.

LENGTH AND WIDTH:They are directly proportional to the length of the fabric. For industrial dyeing, a minimum of 2000 meter of fabric is accepted to be dyed. It is beneficial to go for wider width fabrics instead of longer fabrics. If the width of the fabric is doubled, the cost of processing is not. This is because the overheads and cost of running the material are dependent on the length and not the width.

3. Production costs makes up another eight percent and comprises the costs incurred in running the machinery, maintenance, fuel for power, humidification and other utilities.

SPINNING:Open-end spun yarns, used for coarser yarn count below 20 are cheaper than ring spun yarns because the cost of manufacturing is less. The number of fine filaments used to make the yarn will also affect the cost. Bright yarns are more expensive than dull yarns, and textured yarns are more expensive than flat yarns because of the additional process cost.

WEAVING:The weaving cost is affected by the beam size. If the beam is small in length the cost will be more as beam gaiting and knotting will add to the cost. The quality of mill made fabrics is better than power-loom made fabrics in terms of yarn quality, and hence the cost is higher. Sometimes it can be higher by as much as 25 percent. Wastage of 2-3 percent in warping and weaving and shrinkage of 1-1.5 percent from loom to grey folding stage is included in the weaving cost

4. Worker wages and salaries make up another 8 percent. Fabric manufacturing is a labour intensive process. As a part of their CSR policy many factories train unemployed-unskilled labour and recruit them into the various stages of production. While this sources the factory the much needed labour, it also serves as an additional source of income to the family. The Indirect costs comprise of: 5. Interest on investment, loan, working capital and depreciationthat comprise seven percent, 6. Overheads and administrative expenses like traveling, telephone, couriers, legal issues and taxes make up another seven percent. It may be represented as follows: The big picture is that direct and indirect costs can have influence on the production of fabric. The different parameters that make up the costs of the fabric can be grouped into two different ways. That is, raw material, size and chemicals, production cost and worker wages and salaries make up the direct costs. On the other hand interest on investment, loan, working capital, depreciation and overheads and administrative expenses make up the indirect costs. Amidst these costs, a 10-20 percent profit margin is achieved making fabric production a worthy but intensive process.