Cheers to you! If you’ve made it to the fabric selection stage, you’ve come a looooong way (and we’re proud of you!). The fashion designer’s relationship with fabric is at the heart of the creative process. Choosing the right fabric is fundamental to good design and is crucial to its manufacturing success.

Apparel design and garment production are lengthy processes, and likewise, sourcing your fabric is no quick task. The types of fabrics and textiles out there is endless. Every garment begins with fabric; it is the fabric that brings a design to life. You can dramatically alter your design’s end result by simply changing the fabric you make it from. If you want to ensure that everyone is on the same page and easily be able to classify your product, you need to be able to know how to clearly describe it. Sew, let’s get you headed in the right direction by assisting you with the first step to fabric selection: classifying fabrics. There are numerous ways to classify and measure fabrics. Below are the three most important first steps to classifying the fabric. There are numerous ways to classify and measure fabrics. Remember: all of this information should go in the garment tech pack.

Classifying and Measuring Fabrics

There are numerous ways to classify and measure fabrics. Begin by determining the fiber content or composition: is it cotton, polyester, or blend? Fibers are either synthetic(man-made) or natural. A fiber is the smallest visible unit of any textile product. Fibers are flexible and may be spun into yarn and made into fabrics. This information must be labeled on all garments. Fiber content is a legal requirement in North America and must be disclosed to the consumer.

Beyond fiber content, It is important for a designer-entrepreneur to understand fabric structure in order to select fabrics that will behave as needed for a particular design.

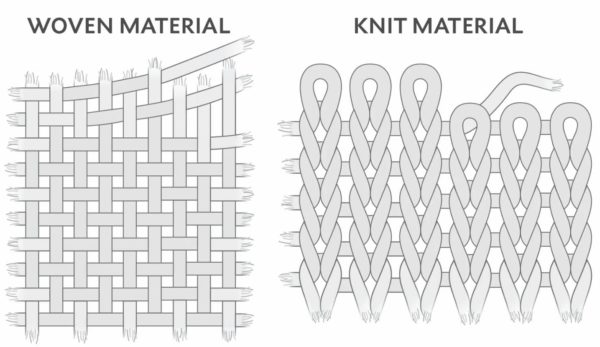

The three types of structures are knits, woven and non-woven. There are many advantages and disadvantages to each method, all of which affect their end use. Woven and knit fabrics are the most common types and they have many differences and similarities. The terms “woven” and “knit” do not refer to specific fabrics, but rather the design or the way the fabric is put together. For instance, cotton is a type of fiber that comes in both knit and woven designs. Each structure can be further classified into construction type; how they are knit together.

The other method includes non- woven fabrics. Fabric such as felting, laminating, and bonding are considered non-woven. It is neither a woven or non-woven.

The easiest way to tell whether a fabric is knit or woven is to look closely at the fabric. Below are some pointers.

1. Fiber Content

It is essential to know how a particular fiber or fiber blend will impact the material’s overall performance qualities such as drape, insulation and wash care. A fiber is the smallest visible unit of any textile product. Fibers are flexible and may be spun into yarn and made into fabrics.

The first step is to begin by determining the fiber content or composition: is it cotton, polyester, or blend? Fibers are either synthetic(man-made) or natural. Common natural fibers include wool, cotton, linen & silk. Common synthetics include polyester, acrylic & nylon.

This information must be labeled on all garments. Fiber content is a legal requirement in North America and must be disclosed to the consumer.

2. Structure/Formation

The second most important description of your product is classification. It is important for a designer to understand fabric structure in order to select fabrics that will behave as needed for a particular design. There are many advantages and disadvantages to each method either knit, woven or non-woven, all of which affect their end use. Weaving and knitting are the most common fabric construction methods.

A. Knit Fabric

Determining if a fabric is a knit

If you see loops, it is a knit fabric. Think of T-shirt, Polo shirt, or leggings. Knit fabrics are made by inter-looping yarns and stretch in both directions. Generally, it’s considered comfortable and is wrinkle resistant. Knits are faster to sew and shrink more than woven fabrics.

- Products made from knitted fabrics

- Products that you want to stretch and have some give

- Used for casual wear, activewear, and form-fitting clothing

- T-shirts

- Sweatpants & sweatshirts

B) Woven Fabric

Determining if a fabric is a woven

Picture a weaver using a loom to create fabric, and you can kind of already visualizing what woven fabric looks like. Think of a shirt or a trouser, or a suit, or denim jeans. They are all made from woven fabrics. Woven fabrics are made by interlacing two sets of yarns and have a checkered pattern when looked at closely; you’ll see this on your denim, suits, and often collared shirts. Yarn sets are known as warp yarns and weft yarns. The fabric manufacturing method of woven fabric is known as weaving. Woven fabrics are made on looms (handloom or power loom) and do not stretch like knits; they stretch only on the bias direction. It is possible to make stretchy woven fabric by using spandex (lycra) yarns, like with stretchable denim pants.

Products made from woven fabrics

- Products that you don’t want to lose their shape by stretching

- Curtains

- Dress pants

- Dress shirts

- Towels

C. Non-woven Fabric

Determining if a fabric is non-woven

The other method includes non-woven fabrics such as felting, laminating, and bonding, made by sticking fibers together using heat, glue, needle punching or felting. Bonded-fiber fabrics are made from webs of synthetic fibers bonded together with heat or adhesives. Non-woven textiles tend to be weaker, easily torn fabrics, as the fibers are not held together in any structured, secure way. Wool felt is an example of non-woven fabric made from animal hair or wool fibers matted together using moisture, heat, and pressure. Felt has no strength, drape or elasticity but it is warm and does not fray.

Products made from Non-Woven fabrics

- Often used to make disposable items such as surgical masks or menstrual hygiene products

- Cleaning cloths such as Jeye Cloths

- Support or strengthening for garments – interfacing, bondaweb

- Children’s toys – Fuzzy Felt, Finger puppets

3. Construction Types

There are different ways of knitting or weaving that change the type of fabric, altering its look, properties, and feel.

Knit Construction Types

Of course, there are many variations of knit fabrics (knit constructions), all serving specific purposes and intended for specific uses on garments:

Interlock Knit: A variation of the rib knit stitch, resembling two separate 1×1 ribbed fabrics that are inter-knitted. Plain (double knit) interlock knit fabrics are thicker, heavier and more stable than single knit constructions. It also has more natural stretch than a jersey knit, is soft to touch, and is identical on both sides. It’s often used in higher-quality babywear.

Jersey (plain knit/single knit): Single knit jersey is lightweight with one flat side and one piled side, most often used for T-shirts. Double knit jersey is two single knit jerseys knitted together with two flat sides for added weight and durability. The difference is that it has a distinct front and back side.

1×1 Rib Knit: Commonly used for sleeves- and neck-bands because it is highly elastic and retains its shape. 1×1 rib knit construction is a pattern of one rib and one flat space, repeated over and over. Both sides of this knit fabric look identical.

1×2 Rib Knit: Also commonly used for sleeves- and neck-bands; highly elastic and retains its shape.1×2 rib knit construction is a pattern of one rib, two flat spaces, one rib, two flat spaces, and so on. 1×2 rib knit has a chunkier appearance compared to 1×1 rib knit.

Double Knit: Made with two sets of yarns, this double-constructed fabric has fine ribs running lengthwise on both sides. Because both sides are often identical, this fabric can be used for reversible garments. Heavy and firm, it usually has almost no stretch in either direction, but does boast good shape retention (cut edges don’t curl). Best used for tailored garments, like jackets and suits.

Woven Construction Types

Like knits, there are several varieties of weaves. The three main weaves include plain, twill, and satin.

Plain weave (plain, twill, satin): Plain weaves are the most simple of all weaves. Same-size warp and weft threads are woven together one by one. This is the simplest and tightest method of weaving. The warp yarn goes over and under each weft thread, creating a fabric with two identical sides. Examples of plain weave fabrics are crepe, taffeta, organdy, cotton calicos, cheesecloth, gingham, percale, voile, and muslin.

Twill weave: Denim is the most popular twill weave fabric; other examples include drill, serge, and gabardine. Warp and weft threads are interlaced, causing diagonal lines to appear on the fabric.

Satin weave: Examples include satin, sateen, Duchess, and damask. The interlacing of the threads are never adjacent to one another; the repeat is usually over at least 4 threads but the warp end interlaces over the 1 weft thread per each pattern repeat. Therefore, the back of the fabric looks very different from the front. Satins and sateens have shiny or lustrous surfaces.

4. Weight

Weight is an important component when it comes to choosing the right fabric for your project. There are two systems of fabric weight categorization, imperial and metric. GSM is a metric measurement meaning grams per square metre – it is how much 1 square metre of fabric weighs. GSM is the most common method used in the industry. Ounce per square yard (oz/sq2) is the imperial measurement, used mainly in the US.

Lightweight fabric: 30-150 GSM

Medium weight fabric: 150-350 GSM

Heavyweight fabric: 350+ GSM

The larger the number, the heavier the fabric. Testing can be done in specialized testing labs, such as SGS and Intertek or measured on a GSM scale. The fabric’s weight significantly impacts its drape, or the way it hangs, which ultimately informs where and how the garment should be worn. Weight also affects comfort, durability, and usage. The weight of the fabric is particularly important when having to choose between two similar fabrics. Be sure that when you’re ordering or even re-ordering fabric that you specify weight so there are no issues!

What are some of your favorite fabrics to work with? Are they woven, non-woven, or knit?

P.S. Like what you see here? There’s more of this juicy information in the Source My Garment book- An insiders guide to responsibly manufacturing offshore. Get your copy here.