The question, “How much for 1000 t-shirts?”, is complex. There are way too many variables to be able to give a universal response. For the apparel to be manufactured right, so many more details are needed, such as brand, size, color, and features before a cost can be estimated. Think about how you would answer the question, “How much does a car cost?” You can buy a car for a couple thousand… of for a couple hundred thousands – there’s no one answer, and it depends on the quality and features you want!

Still, it’s important to know an estimate of what your garment is going to cost, so you can make sure it is feasible, reasonable, and when priced to sell, it’s the right price point for your consumers. Here’s what you’ll need to get a better idea of what it’s going to cost you.

The only way a factory can give you a proper estimate is by taking a look at a physical sample, prototypes, tech packs, line sheets, target costs, and fabric swatches are just a few of the things your manufacturer will need to review. Using these, they’ll be able to stitch a counter sample and will be able to make an accurate cost estimate for you.

Without the following, it’s just a guess. And gambling with money is never a good idea in any business plan. Here’s a list of all of the things to include in your pre-production package to ensure an accurate estimate!

Pre- Production Package:

1. Garment Tech packs for every style – (insert link to post when ready to post)

2. Fabric swatches – Mount a 10” by 10” fabric swatch to a piece of cardboard and label with the date, quality expectations, fabric content, weight, structure and any other details your manufacturer will need.

3. Color standards – Provide a color standard or Pantone number for the factory to reference and color match.

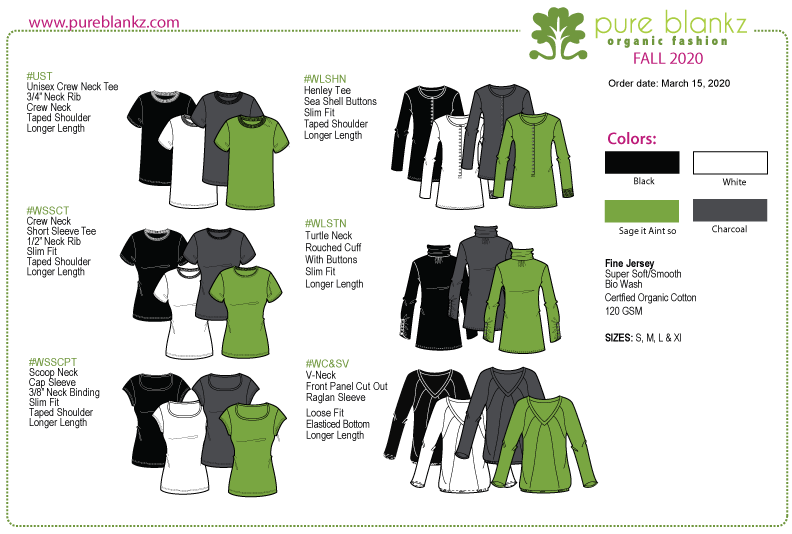

4. Line Sheet – Provide a one page visual of all the styles and colorways you plan to order.

5. Quality references – Provide samples for the factory to reference as a quality standard. A physical sample of print quality, trim, or construction method you could not achieve on your prototype is the best way to communicate your standards to the factory. Label or mount each reference sample (style number, brand name, date, and any other notes to help the factory address your expectations).

Provide a quality standard for packaging, embellishments, label, hang tags, embellishments, and trims to the factory. Keep one set for yourself. Take a high-resolution photo of each in case you need to refer to it.

6. Prototypes – Mark any comments/issues directly on the product using masking tape if it is not exactly as you want it manufactured. For example, call out the print location if the print is not on the sample. Label each sample with date, style number, size, and brand name. Take a high-resolution photo of the front and back

7. Patterns – CADs (Computer-aided Designs) should be emailed, or supply the hard copy of the patterns. Keep a duplicate on hand.

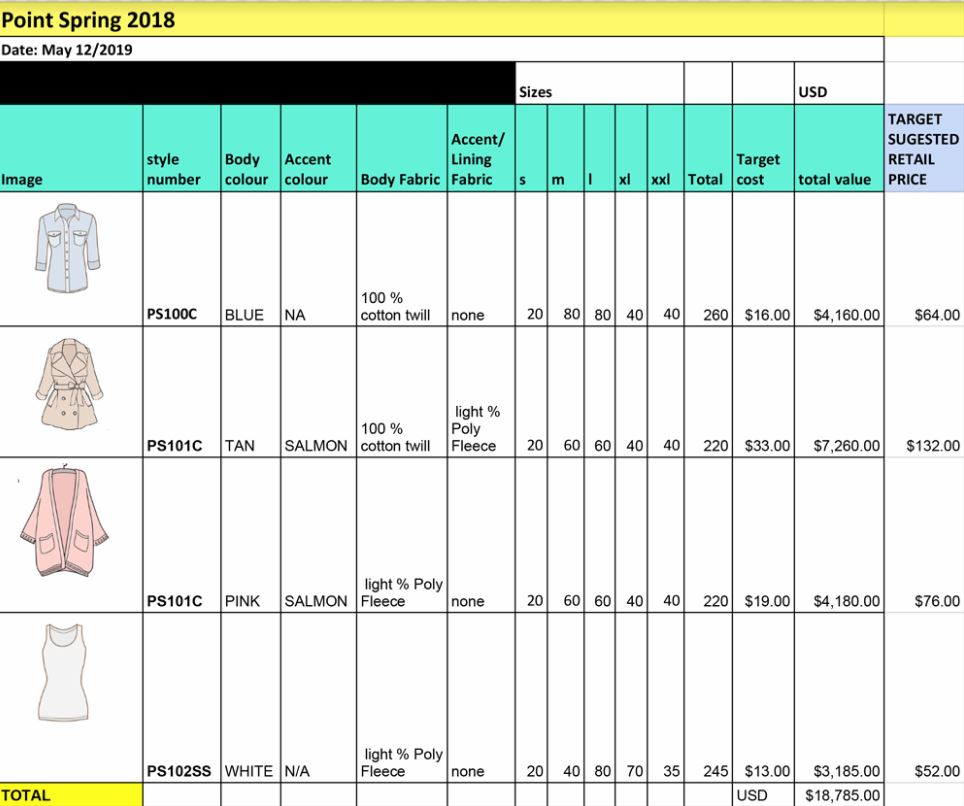

8. Mock Purchase Order – Outline the target costs based on required styles, colors, quantities, sizes, delivery date, and testing requirements.

Follow this guideline to ensure you get an accurate estimate from your garment factory. With these numbers, you can have a better understanding of how to plan your business. An estimate helps you determine whether the garment is feasible and if changes need to be made before it hits production. With these guidelines, you’re well on your way to getting your pieces into production and onto the runway!

P.S. Have a tech pack, prototype, and fabric standard? Contact us for a quote and we can get your product manufactured and shipped to your door. Let us take care of it all for you.

How was your experience been working with a factory to get an estimate for your products? Get insider tips from our book. Get it here!